Fujitsu's 'Nanohole' Tech Could Triple Hard Drive Capacity

Last November, we reported on Fujitsu's efforts to overcome a curious problem with the physics of hard disk drives: storing magnetic data at densities that are smaller than the grains of the underlying ferromagnetic medium should physically allow. The company's solution involved a combination of lasers to locate precise locations on the drive, and also to pre-heat data spots to make them more conducive to holding data at precise locations.

But all that assumes that the precise locations in question...already exist. Yesterday, we learned from Fujitsu how they intend to accomplish that, and we also got a peek at some areal density goals.

The problem facing HDD engineers has been that perpendicular recording - the process that has already led us to the one-terabyte era for desktop storage - can only go so far. Even higher-capacity drives will be needed soon, not for storing spreadsheets but for serving media...unless CE manufacturers expect every digital home in the 2010s decade to drive their own SANs.

Fujitsu's next big idea literally came from those aluminum "hologram" stickers you frequently see on the front of cereal boxes, and the certification tape of sealed software cases. Making those pretty colors onto aluminum uses a process called anodization, which is a kind of electrolytic "washing" that leaves pits beneath its surface. The non-pitted regions become oxidized to form what's called alumina.

This pitting can change the color of aluminum, but it also increases its corrosion resistance. The size of those pits has already been known to be "nanoscale." What if the location of those pits could be predetermined, so a manufacturing process could place pits in an exact arrangement? Then those pits could be exploited for use as bits, in the data sense.

|

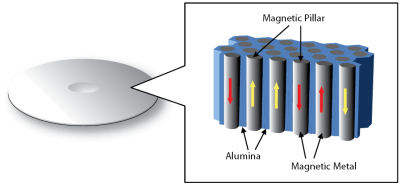

Cobalt is seeded within specially created grooves of anodized aluminum, leaving behind pillars that direct bits right to their holes. (Courtesy Fujitsu) |

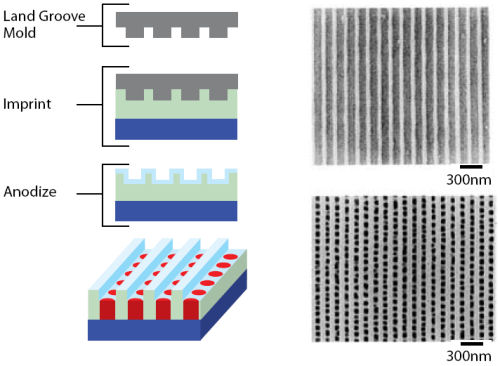

The solution Fujitsu engineers came up with is in a sense anything but novel, and proof positive that Edison had the right idea a century ago. First, they create a mold of the inverse of the surface of their nanoscale HDDs, and into this mold they inscribe grooves. If you've ever played a vinyl record album...yes, that kind of groove, except just not spiral. Its pitch is just 45 nm wide, which is perfect for the spot size of the guiding laser Fujitsu has in mind. This "land groove mold" is then imprinted onto the HDD surface, with the embossed areas carving little notches, like in a potato garden, where pits can be planted and grown.

If you've ever gardened, you know the secrets to beautiful flora are frequent watering and proper fertilization. In Fujitsu's case, the "watering" comes from the anodization wash. This creates alumina pillars that enable the grooves to be more magnetically stable than the outer surface - so that magnetic data is drawn toward the grooves where we want it to be. For fertilizer, Fujitsu uses cobalt, which is a cheap, ordinary material that happens to be very, very small. The alumina pillars create fenceposts, while the cobalt-induced pits give the bits someplace warm and comfortable to rest.

Yesterday, Fujitsu's public relations threw out a number for the press to chew on: One terabit per square inch areal density, achievable by 2010. This is a repeat of what the company said last year, when the company announced the optical spotting technique; and again last April, when Fujitsu first announced it had achieved nanohole spots at 25 nm depth. (Yes, Fujitsu actually announced this back in April, to the Asian press.)

One Tb/sq. in. is roughly three times the theoretical maximum capability of perpendicular HDD media today, and more than five times what's commercially available. But that number is nowhere close to where Fujitsu engineers are really aiming: The theoretical areal density achievable through this "nanohole" technique, according to Fujitsu documents, is actually four terabits per square inch.

And since the dynamics of this technique are predicated on the physical sizes of the materials involved - for instance, cobalt molecules - there's actually a probability, if we read Fujitsu's documents correctly, that it won't work its way up to 4 Tb/sq. in.; rather, it may have to jump over this strange 1 Tb/sq. in. number all the way to 4, and work its way up from there.

At any rate, what Fujitsu's PR is saying is to expect 2.5-inch and 3.5-inch HDDs with capacities at least three times what we're accustomed to today, in three years' time...which seems just about right.

|

| Fujitsu's "land grooves" create pits where bits seed themselves, as seen under the electron microscope. (Courtesy Fujitsu) |